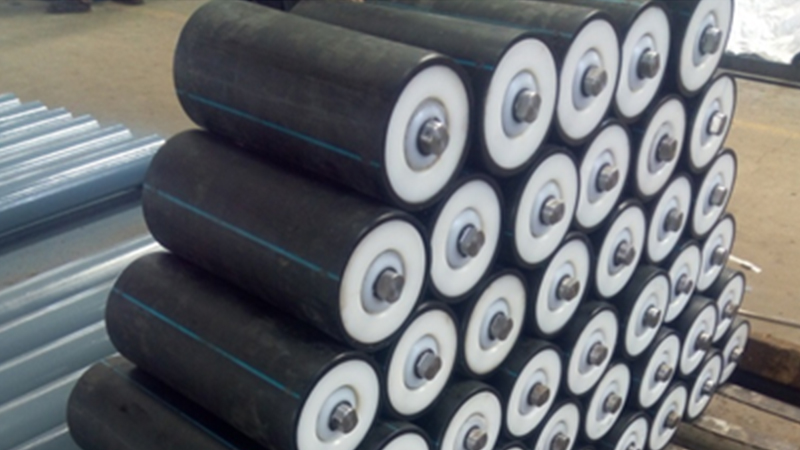

Idlers are the heart of a conveyor, since reliability and longer life can reduce down time for the conveyors, effect reduction in power consumption and increase belt life. Rollwell idlers operate with very low coefficient of friction and are designed for reliable and guaranteed performance of upto 60,000 hours

We manufacture all types of Idlers/Roller like :

- Troughing / Flat Carrying Idlers.

- Troughing / Flat Impact Idlers.

- Self Aligning Carrying/Return Idlers.

- Flat / V Roll Return Idlers.

- Self Cleaning Return Idlers.

- Transition Idlers.

- Garland Idlers.

Salient features of Rollwell Rollers :

- Rollers are manufactured from ERW pipes as per IS: 9295, which are specially made for Idlers application. These pipes are specially made with tight tolerances related to straightness and ovality.

- Pipes are bored at both ends simultaneously using a special purpose Double Headed Boring machine. This will maintain concentricity of shaft at both ends of idlers and will limit the run out of the idlers

- The bearing housings are manufactured from Extra Deep Drawn CRCA sheets.

- The Bearing seating, flange diameter and back facing of the bearing housing are machined in a single setting on a Special Purpose Machine to ensure absolute concentricity.

- Bearing Housings are welded to the pipe at both ends simultaneously by CO2 welding.

- Roller shafts are made of bright bar.

- We use only genuine bearings from SKF/FAG and they are sourced directly from the manufacturer.

- Vertical labyrinth type sealing system is provided for the bearings. The sealing system consists of Double Labyrinth Seal, made of CRCA sheet. Glass beaded Nylon seal is provided at back of the bearing to avoid grease entering in side the pipe. A neoprene rubber seal is provided on top of the outer labyrinth seal to prevent any water and dust from entering inside the idler.

- After the idlers are assembled each idler is continuously rotated for a minimum period of 15 minutes for both freeing of the idler as well as testing for any heating of the bearing.

- As per the Quality Assurance Plan, idlers are tested for Water and Dust Penetration in specially built Jigs.

- The rolling resistance of Rollwell idlers is as low as 0.01 as against allowable value of 0.02 and design value of 0.03 for standard rollwers.